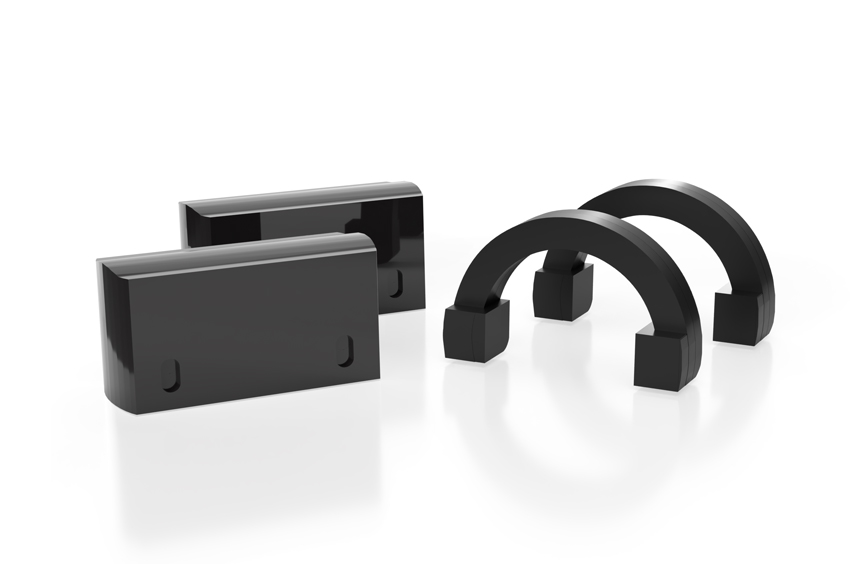

A blowout preventer (BOP) is a large, high-pressure safety valve system used to prevent the uncontrolled release of oil or gas from a well in the event of a blowout. BOPs incorporate two sets of seals: inner and outer seals. They work together to contain well fluids.

The inner seal acts as the primary barrier, preventing fluids from escaping into the environment. It is typically made from high-strength rubber compounds capable of withstanding extreme pressures and temperatures. Composed of hydrogenated nitrile and carbon steel. Common line sizes include 3/16”, 7/32”, ¼”. 5/16”, 3/8”, 15/32” and slickline.

The outer seal serves as a backup system, activating if the inner seal fails. This system often uses shear rams or blind rams, which can be hydraulically engaged to clamp onto or cut through the drill pipe or casing, fully sealing the well. Available in Hydrogenated Nitrile.