Micro-Vu Excel | |

|

|

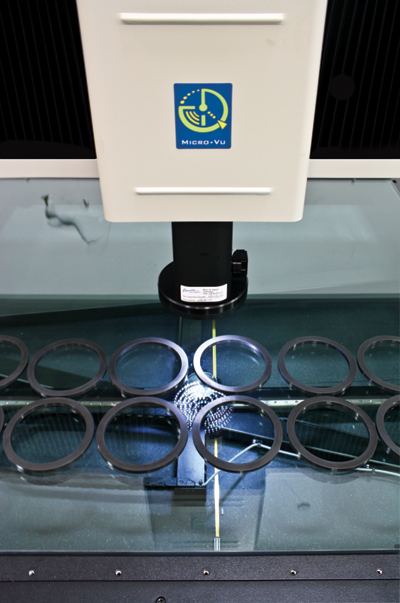

Hi-Tech’s Newest Optical Measurement Inspection Device

The Excel’s measuring surface area is 41’’ x 41’’ with the ability to measure a height of 9”. This allows Hi-Tech Seals to measure parts and components approximately two times larger than what our manual optical measurement can measure. When dealing with smaller components, the Excel can be programmed to measure multiple components consecutively. Hi-Tech Seals engineers, draftsmen and quality control department utilize the Excel’s automated feature and zoom capabilities to accurately measure a part or component’s ID, OD, C/S, heights, angles, and even areas and volume. This information helps to closely examine the smallest details regarding the parts’ profile, angles and dimensions.

The Excel is a unique investment offered to provide customers with improved services and quality control. For more information on the Micro-Vu Excel, contact Hi-Tech Seal’s representative. |

|

Hi-Tech Seals has expanded our engineering capabilities to include the Micro-Vu Excel, an automated optical measurement device. The Excel is a unique investment offered to provide customers with improved services and quality control. It allows Hi-Tech Seals to inspect and measure parts and components faster and more accurately than previously capable.

Hi-Tech Seals has expanded our engineering capabilities to include the Micro-Vu Excel, an automated optical measurement device. The Excel is a unique investment offered to provide customers with improved services and quality control. It allows Hi-Tech Seals to inspect and measure parts and components faster and more accurately than previously capable.

Hi-Tech Seals’ quality controls staff operates the Excel to inspect newly arrived parts. This allows Hi-Tech Seals to verify the accuracy of the part against the supplied drawing and the consistency among parts. The Excel can also confirm the tolerances of machined parts to the highest industry standards.

Hi-Tech Seals’ quality controls staff operates the Excel to inspect newly arrived parts. This allows Hi-Tech Seals to verify the accuracy of the part against the supplied drawing and the consistency among parts. The Excel can also confirm the tolerances of machined parts to the highest industry standards.