Hi-Tech Seals offers spliced and vulcanized O-rings in standard and square profiles, multiple cross sections, and various materials. We also offer quad ring profiles upon request. Customers can purchase our O-ring cord in cut lengths, splicing kits or through our in-house splice and vulcanizing service.

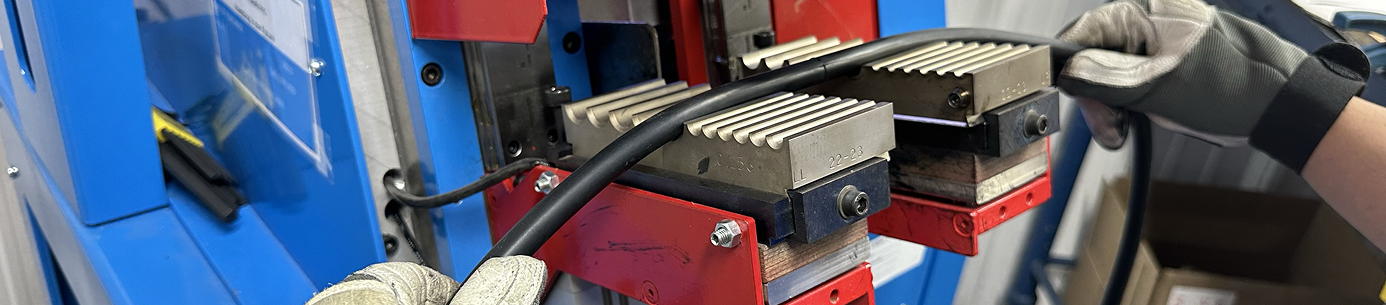

Spliced and vulcanized O-rings are made by cutting extruded cord stock into lengths and then joining them together (splicing). The ends are spliced together by applying a heat-activated bonding agent and placing them in a die for a specific length of time. This process forms a molecular connection to achieve a strong bond.

Spliced and vulcanized O-rings are excellent replacements for any unique-sized static O-ring, withstanding up to approximately 1,200 psi. They are used in various industries including automotive, transportation, construction, food processing, power generation, and more.

Splice & Vulcanizing Advantages

- Strong consistent bond quality

- Available in a wide range of materials

- No tooling costs

- Quick turnaround times

- Ability to accommodate large diameters and custom, non-standard sizes.

Materials

Choose from a diverse range of high-performance rubber materials suitable for various applications. Common materials include but are not limited to:

Nitrile

Viton™/Fluorocarbon

Neoprene/Chloroprene

Ethylene Propylene (EPDM)

Silicone

Natural Rubber

Viny

Beyond O-Rings

Our splice and vulcanizing expertise extends beyond O-rings to gaskets and other sealing products. All vulcanized products benefit from the same precision that we apply to our vulcanized O-rings. This ensures a high-quality, superior bond suited for diverse applications. Our range of advanced vulcanizing capabilities includes, but is not limited to:

- Extruded Profiles

- Gaskets

- Split Rotary Seals

- Rubber-to-metal Bonding

- Encapsulated O-rings

- Industrial Tubing

- Continuous Molded Products

- Other bonding services

Cut-Length Calculator

Cut Length

using ID

Cut Length

using OD