BoKure™ urethane components are produced in-house through our Cast Urethane division. Our team specializes in the design, development, and manufacturing of both simple and complex urethane components. These components offer excellent performance characteristics, helping extend product life, increase equipment run time, and reduce costly maintenance.

BoKure™ urethane compounds are a great alternative to rubber, plastic, or metal, especially in applications where impact resistance, corrosion protection, or wear performance is critical. BoKure™ Urethane is more versatile and offers significant wear resistance over other rubber and plastic components.

We manufacture both standard and custom components, including rollers, spacers, protective products, bushing impact pads, and more. When needed, our team can also reverse engineer components with low tooling costs to meet specific application requirements.

BoKure™ Urethane Advantages

- Superior abrasion and impact resistance

- Exceptional load bearing ability

- Excellent cracking and tear resistance

- Outstanding performance in elevated temperatures

- Remarkable low-temperature flexibility

- Outstanding resistance to a wide range of chemicals

BoKure™ Urethane Compounds

BoKure™ urethane compounds are formulated with high-performance resins, curatives, and additives—each engineered to deliver distinct advantages and capabilities. Our offering includes two primary urethane types: polyether and polyester. We can assist with selecting the optimal compound to meet application requirements and environmental demands.

Durometers

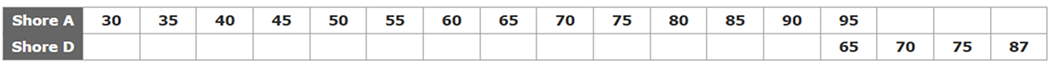

BoKure™ Urethane components are offered in a wide range of hardness, from as soft as an eraser to as hard as a bowling ball. Hi-Tech Seals can maintain urethaneʼs toughness and resilience while manufacturing components for Shore A and Shore D durometers. Our in-house capabilities allow us to manufacture dual-durometer urethane components.

Incorporate

Metal Hardware

Hi-Tech Seals can incorporate metal hardware into your urethane components.

This ability allows us to provides three key opportunities:

Metal Threads

Metal threads can be incorporated into your urethane component. Metal threads will allow the urethane component to be screwed into place.

Square Cut Ring

Create split parts by incorporating metal studs into your urethane component. Hi-Tech Seals can manufacture components in two pieces. On one of the components we can mould in a stud that will insert through the other component. Split parts allow for easy installation without the trouble of disassembling the machinery.

Quad Ring

Incorporate a rigid metal support structure within the urethane. The metal hardware allows the urethane to benefit from the strength of the metal while exhibiting the properties of a urethane.

Over Moulding

Hi-Tech Seals offers an over moulding service as a means to recycle worn parts. Over moulding is cost effective and environmentally friendly. The over moulding process prolongs the life of existing rubber and plastic components by replacing the worn off area of the part with a urethane blend. Due to BoKure™ urethane’s improved wear and load bearing ability, over moulded components can even outperform many OEM components.

If a sample component is available, Hi-Tech Seals will use the sample to create the cast. If a sample component is unavailable, a cast can be formed from a part created on our 3D printer or manufactured from our CNC machine. Once the cast is created, the worn component is placed into the proper position, and the urethane blend fills the empty space in the cast.

Custom Colours and Identification Marks

We can manufacture urethane components in custom colours and include logos, part numbers, and dimensions for enhanced brand recognition and easy traceability of proprietary parts.