Technically Speaking Injection Moulding |

This edition of Technically Speaking will continue with our third instalment in a six part series on moulding techniques. Previous editions have introduced five different types of moulding techniques and covered compression moulding. This instalment will discuss injection moulding.

|

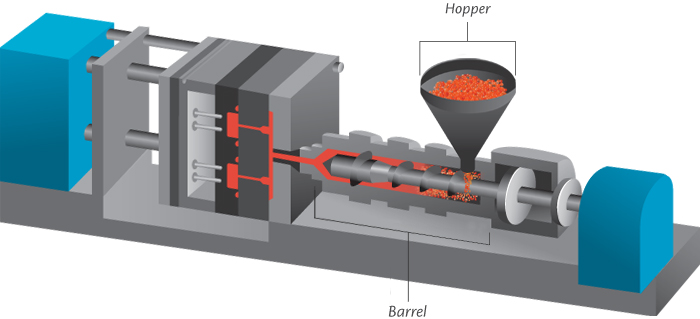

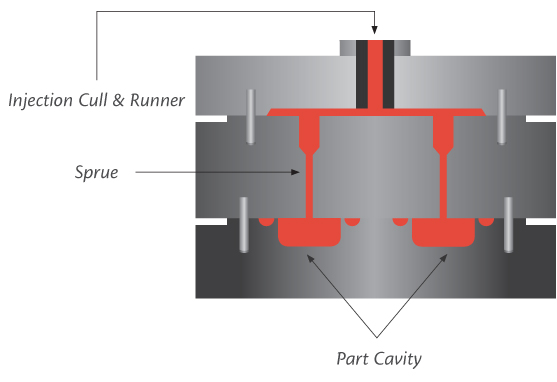

Injection moulding is a common and very complex moulding technique. It starts by feeding uncured plastic or rubber granules through a hopper into a barrel. The granules pass through the barrel by a reciprocating screw, where they are heated. When the barrel has enough molten material, a hydraulic system drives the screw forward, forcing the material into the sprues, and into the cavity. The part will remain in the cavity until it has cooled. This manufacturing process can be highly automated and can take as little as three seconds to mould a component.  The material that remains in the sprue after the mould cavity has been filled can either be left to cool, or remain heated. If this material cools as the part cools, it will be ejected with the part. This is called a cold runner system and is comparatively cheaper to produce and maintain than a hot runner system. A hot runner system is a more complicated system that keeps the material hot as the part cools. After the part is ejected, the material in the spru remains hot and is injected into the next part. A hot runner system reduces or eliminates material waste and yields a higher productivity due to reduced process time. The material that remains in the sprue after the mould cavity has been filled can either be left to cool, or remain heated. If this material cools as the part cools, it will be ejected with the part. This is called a cold runner system and is comparatively cheaper to produce and maintain than a hot runner system. A hot runner system is a more complicated system that keeps the material hot as the part cools. After the part is ejected, the material in the spru remains hot and is injected into the next part. A hot runner system reduces or eliminates material waste and yields a higher productivity due to reduced process time.

Delicately shaped parts are well suited for the injection moulding process, as the high pressure forces the material into all corners of the mould’s cavity. The pressure can be upwards of 29,000 psi during manufacturing. Parts with metal or plastic inserts are also well suited for the injection moulding process. This is due to the moulds remaining closed during the entire injection and curing process. This allows the inserts to be held firmly in the correct position, without fear of it shifting. To learn if compression moulding is the most effective way to manufacture your part, contact a Hi-Tech Seals representative. |