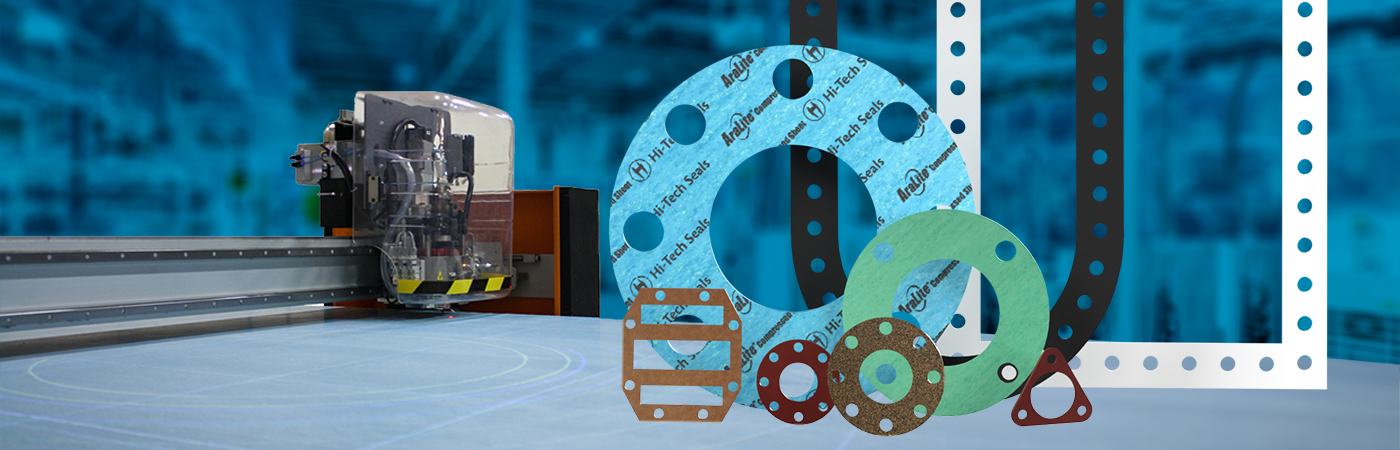

Rapid Gasket is Hi-Tech Seals’ in-house gasket manufacturing service. It allows us to create standard and custom gaskets to provide quick turnaround times for our customers, minimizing downtime and reducing operating costs.

Fast and Precision Measuring

Customers may send gasket drawings (in .DXF format) or provide a gasket sample which we can reverse engineer using our LaserQC® machine. It scans the sample, processes the design within seconds, and outputs a production-ready file.

We also provide on-site gasket measuring service for a wide range of applications such as treaters, free water knockouts, line heaters, dehydration tanks, and custom flanges. A qualified technical specialist will visit the customer’s facility to measure gasket applications using an advanced 3D scanner to ensure fast and accurate data collection.

Material Selection

For quick turnarounds and to meet diverse application and industry requirements, we stock a wide range of materials in various sizes and thicknesses (1/64” to ¼”). Our inventory includes high-quality rubber, plastic, and composite sheet materials. They are available in commercial, industrial, and premium grades. Select materials are FDA-compliant and certified to NSF and MIL-SPEC standards.

Manufacturing Process

Once materials are selected and drawings are finalized, our drafting team then exports the file directly into our knife-cutting equipment for rapid gasket production. Whether for standard profiles, complex designs, or custom-cut solutions, our knife-cutting equipment delivers clean, accurate cuts without compression marks. The cutting surface accommodates sheet materials up to 60” x 120”. For gaskets exceeding these dimensions, we apply dovetail or skiving techniques.

On-Time Delivery and Streamlined Reordering

Orders are typically fulfilled and delivered within approximately two days, with rush orders accommodated for urgent needs. During on-site gasket measurement, our technical specialist can also assess other consumable components, such as anodes, pigtails, isolation kits, studs, nuts, and spiral wound gaskets. Customer orders are recorded in our Lease Site Designation Management System (LSDS), which generates a unique LSDS number. This number serves as a reference for the customer’s equipment and order history, making future reordering fast and efficient.

For more information about Rapid Gasket or to request a quote, email us at gaskets@hitechseals.com