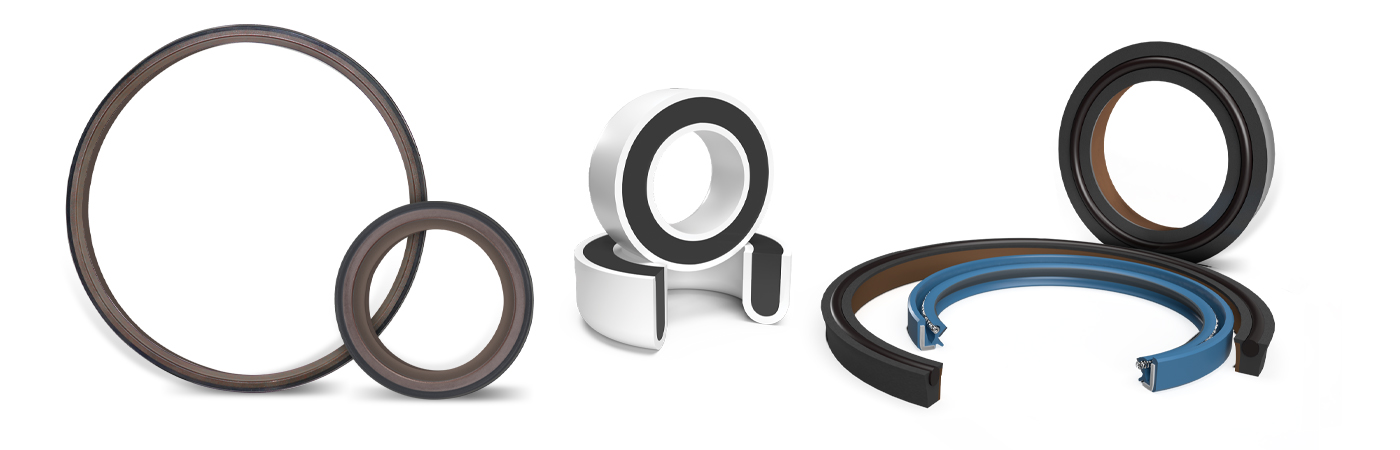

While many companies shy away from recommending PTFE-bonded parts due to its non-stick or slippery characteristics, Hi-Tech Seals embraced the challenge. Using a proven bonding method, we successfully joined rubber to PTFE, combining the benefits of elastomers and PTFE to deliver reliable performance in challenging applications.

A Breakthrough in Durable Bonding

Polytetrafluoroethylene or PTFE is a non-stick or slippery material. It is commonly known as the brand Teflon®, used in non-stick cookware and industrial products. Its attributes are the primary reason why bonding it to other materials remains a challenge. Yet, through advanced bonding techniques that we developed, we were able to bond it to elastomers, rendering a durable and long-lasting bond.

As a result, the bonded components were able to provide the necessary lubricity while retaining the elasticity of rubber. Moreover, bonding rubber and PTFE components into a single part simplifies the installation process owing to the lesser number of separate components to assemble. PTFE serves as an inert barrier protecting the elastomer against harsh chemical attacks. It also functions effectively as an anti-extrusion ring.

Let’s Talk Advanced Sealing Solutions with PTFE-Elastomer Bond

PTFE can be either virgin or reinforced with specialized fillers to meet specific performance requirements. Selecting the appropriate PTFE formulation is just as important as choosing the right elastomer to ensure optimal material synergy and performance. Hi-Tech Seals can bond PTFE with diverse rubber materials, including nitrile (NBR), hydrogenated nitrile (HNBR), ethylene propylene (EPDM), fluorocarbon (FKM), and silicone.

Wondering if rubber to PTFE bonded parts could improve your application’s performance? Contact our sealing specialists for more information on dimensions, capabilities, and material benefits. Our expertise in bonding rubber and PTFE could be exactly what your application needs.